The company can customize the production of various styles of mirror stainless steel plate, welcome to send an email to ask me

1. On the surface of stainless steel, there are deposits of dust or heterogeneous metal particles containing other metal elements. In humid air, the condensed water between the deposits and the stainless steel connects the two into a micro-battery, which triggers an electrochemical reaction , the protective film is damaged, called electrochemical corrosion.

2. Organic juices (such as vegetables, noodle soup, sputum, etc.) adhere to the surface of stainless steel. In the presence of water and oxygen, organic acids are formed, and organic acids will corrode the metal surface for a long time.

3. The surface of stainless steel adheres to substances containing acids, alkalis and salts (such as alkali water and lime water splashing from the decoration walls), causing local corrosion.

4. In the polluted air (such as the atmosphere containing a large amount of sulfide, carbon oxide, nitrogen oxide), in the presence of condensed water, the formation of sulfuric acid, nitric acid, acetic acid liquid spots, causing chemical corrosion The above conditions can cause the protective film on the stainless steel surface. Damage causes rust.

The corrosion resistance of stainless steel mainly depends on its alloy composition (chromium, nickel, titanium, silicon, aluminum, manganese, etc.) and internal structure, and the main role is chromium. Chromium has high chemical stability and can form a passivation film on the steel surface to isolate the metal from the outside world, protect the steel plate from being oxidized, and increase the corrosion resistance of the steel plate. After the passivation film is destroyed, the corrosion resistance decreases.

Stainless steel plate is generally a general term for stainless steel plate and acid-resistant steel plate. Introduced at the beginning of this century, the development of stainless steel plate has laid an important material and technical foundation for the development of modern industry and scientific and technological progress. There are many types of stainless steel plates with different properties. It has gradually formed several categories in the development process. According to the structure, it is divided into four categories: austenitic stainless steel, martensitic stainless steel (including precipitation hardening stainless steel), ferritic stainless steel, and austenitic plus ferritic duplex stainless steel. The main chemical composition or some characteristic elements in the steel plate are classified into chromium stainless steel plate, chromium nickel stainless steel plate, chromium nickel molybdenum stainless steel plate, low carbon stainless steel plate, high molybdenum stainless steel plate, high purity stainless steel plate, etc. According to the performance characteristics and uses of the steel plate, it is divided into nitric acid-resistant stainless steel plate, sulfuric acid-resistant stainless steel plate, pitting corrosion-resistant stainless steel plate, stress corrosion-resistant stainless steel plate, high-strength stainless steel plate, etc. According to the functional characteristics of the steel plate, it is divided into low temperature stainless steel plate, non-magnetic stainless steel plate, free-cutting stainless steel plate, superplastic stainless steel plate, etc. The commonly used classification method is to classify according to the structural characteristics of the steel plate, the chemical composition characteristics of the steel plate and the combination of the two. Generally divided into martensitic stainless steel, ferritic stainless steel, austenitic stainless steel, duplex stainless steel and precipitation hardening stainless steel, etc. or divided into two categories: chromium stainless steel and nickel stainless steel. Wide range of uses Typical uses: pulp and paper equipment heat exchangers, mechanical equipment, dyeing equipment, film processing equipment, pipelines, exterior materials for buildings in coastal areas, etc.

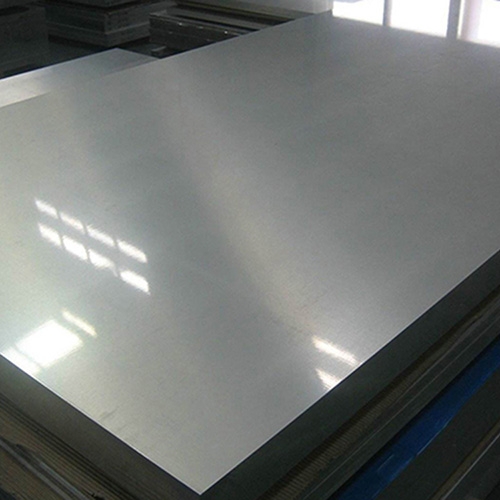

The stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, and is resistant to corrosion by acids, alkaline gases, solutions and other media. It is an alloy steel that does not rust easily, but not absolutely rust-free.