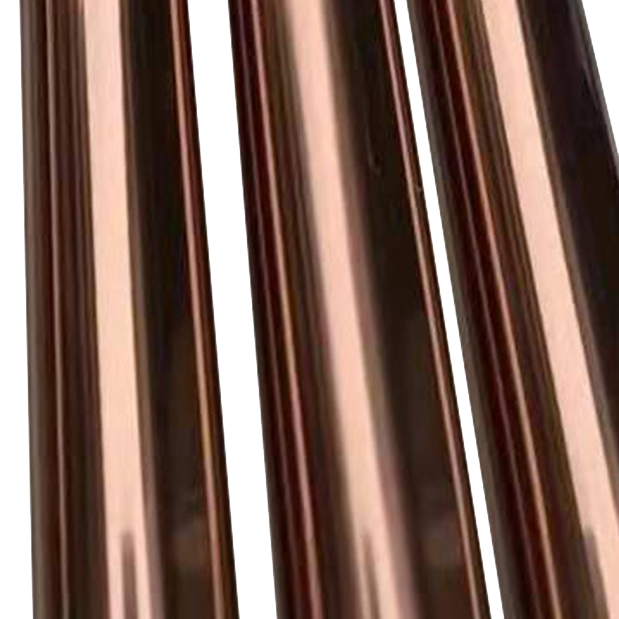

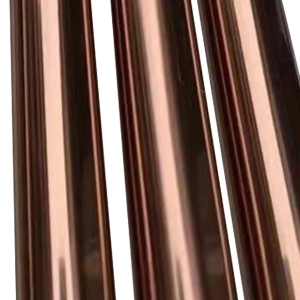

High quality stainless steel round tube

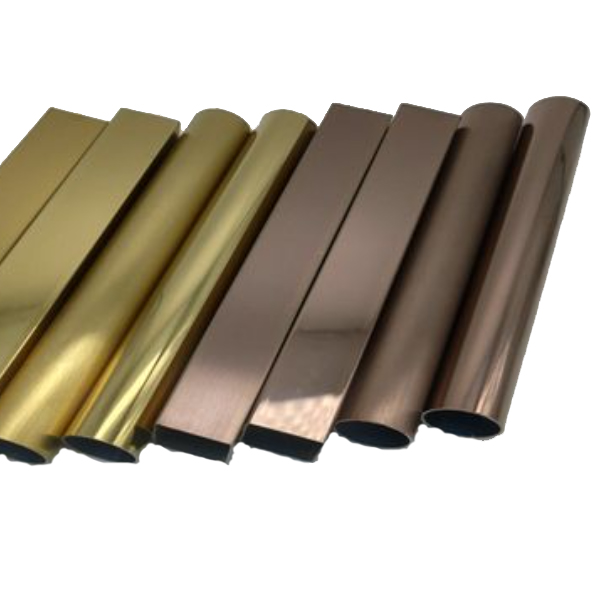

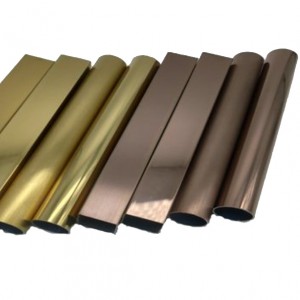

We follow the management principle of "Excellent Quality, Excellent Service, Excellent Position", and we are dedicated to China Decoration 201 202 304 316 430 410 stainless steel pipes, and sincerely create and share success with all our customers. those who are interested. We firmly believe that our solution is right for you.

China's most professional stainless steel pipe supplier, polished stainless steel welded pipe. We can meet the diverse needs of domestic and foreign customers. Warmly welcome new and old customers to consult and negotiate. Your satisfaction is our driving force! Let us write a brilliant new chapter together!

The surface treatment of the stainless steel round pipe is one of the key factors that determine the anti-corrosion service life of the pipeline. It is the premise of whether the anti-corrosion layer and the stainless steel round pipe can be firmly combined. It has been verified by research institutions that the life of the anti-corrosion layer depends on factors such as the type of coating, coating quality and construction environment. The requirements for the surface of stainless steel round pipes are constantly explored and summarized, and the surface treatment methods of stainless steel round pipes are continuously improved.

1. Pickling of stainless steel round pipes is generally carried out by two methods of chemical and electrolytic pickling. Pipe anti-corrosion only uses chemical pickling, which can remove oxide scale, rust and old coatings reprocess. Although chemical cleaning can make the surface achieve a certain degree of cleanliness and roughness, its anchor pattern is shallow and it is easy to cause pollution to the environment.

2. The spraying (throwing) rust removal of the stainless steel round pipe is driven by the high-power motor to drive the spraying (throwing) blades to rotate at a high speed, so that the abrasives such as steel sand, steel shot, iron wire segment, and minerals can affect the surface of the stainless steel round pipe under the action of centrifugal force. Spraying (throwing) treatment can not only completely remove rust, oxides and dirt, but also achieve the required uniform roughness under the action of violent impact and friction of abrasives.

After spraying (throwing) rust removal, it can not only expand the physical adsorption on the surface of the pipe, but also enhance the mechanical adhesion between the anti-corrosion layer and the surface of the pipe. Therefore, spraying (throwing) rust removal is an ideal rust removal method for pipeline anticorrosion. Generally speaking, shot blasting (sand) derusting is mainly used for inner surface treatment of pipes, and shot blasting (sand) derusting is mainly used for outer surface treatment of pipes.

3. Stainless steel round tube cleaning, use solvent and emulsion to clean the steel surface to remove oil, grease, dust, lubricant and similar organic matter, but it cannot remove rust, oxide scale, welding flux, etc. It is only used as an auxiliary means in production.

4. To remove rust from stainless steel round pipe tools, mainly use tools such as wire brushes to polish the surface of the steel, which can remove loose or raised oxide scale, rust, welding slag, etc. The rust removal of hand tools can reach Sa2 level, and the rust removal of power tools can reach Sa3 level. If the steel surface is adhered to a firm scale of iron oxide, the rust removal effect of the tool is not ideal, and the anchor pattern depth required for anti-corrosion construction cannot be achieved.

Pay attention to the importance of surface treatment in production, and strictly control the process parameters during rust removal. In actual construction, the peel strength value of the anti-corrosion layer of the stainless steel round pipe greatly exceeds the standard requirements, which ensures the quality of the anti-corrosion layer. On the basis, the technological level is greatly improved and the production cost is reduced.